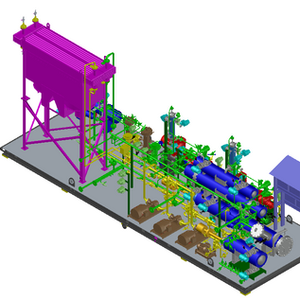

Process Skid Design

How Process Skids are designed at Destech?

At Destech, our process skid design involves the creation of modular skids that house various necessary equipment's, piping and structures. These type of modular packages are designed to be easily integrated into a larger system.

This approach offers several advantages, including cost saving, faster project timelines and easier maintenance.

Typical process involved in designing a modular process skid packages are

-

Project Undertaking

-

Kick off Meating

-

Preliminary Design

-

Detailed Engineering

-

3D Model Reviews

-

Structural Design

-

Coordinating with other departments

-

Preparation of fabrication Drawings

-

Issue for Construction Drawings

-

Documentation

Compressor types we work

Oil Flooded Screw Type

Centrifugal Type

Reciprocating Type

Diaphragm Type

Process Skids we have experience

Gas Compression Skids

Refrigeration Skids

BOG Skids

Pump Skids

Metering Skids

Filter Skids

Trailer Mounted Skids

Ammonia Skids

Vapour Recovery Skids

Pressure Reducing Stations

Air Compressor Skids

Lube Oil Skids

Skid Design & Calculations

-

Pipe Size & Thickness Calculation

-

Pressure Drop Calculation

-

COG Calculation

-

Pipe Support Design

-

Compressor & Motor Support Design

-

Lifting Lug Design & Calculation

-

Plot Plan & Equipment Layouts

-

3D Modeling of Skid

-

Line LIst

-

Bill of Materials (BOM)

-

Pipe Stress Analysis

-

Lifting Analysis

List of Drawings

-

General Arrangement Drawing

-

Foundation & Loading Data

-

hazardous Area Drawing

-

Lifting Drawing

-

Pipe support Location

-

Pipe support detail Drawings

-

Piping Isometric Drawings

-

Equipment Support Drawings

-

Instrument Location Drawings

-

Equipment Location Drawings

-

JB, LOP & Control Panel location Drawings

-

Wiring Drawings

-

Tubing Layouts

-

As-Built Drawings